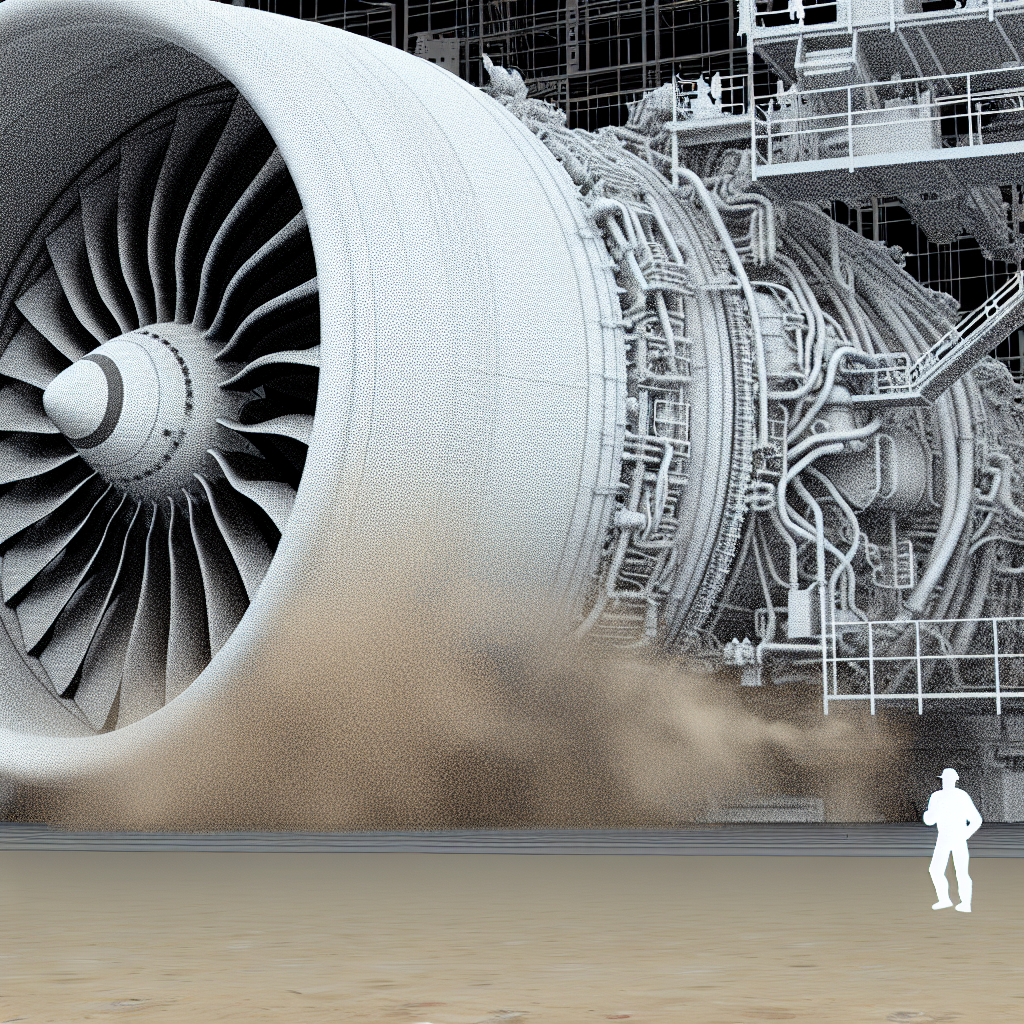

BOSTON – GE Aerospace has successfully completed its initial set of GE9X dust-ingestion tests in 2022, which included 1,600 engine-run cycles with no adverse findings reported.

This testing plays a crucial role in preparing for the GE9X engine, which boasts a thrust of 105,000 lbs and is set to power Boeing’s much-anticipated 777-9 aircraft, expected to begin deliveries next year.

GE Engine Testing Phase

On May 28, GE announced that it is nearing the completion of the second round of GE9X dust-ingestion tests, following up on the initial tests conducted in 2022.

The GE9X is the first engine within GE’s lineup to undergo such dust-ingestion testing prior to entering service. This effort reflects the company’s heightened focus on enhancing durability, prompted by various reliability concerns impacting both GE and its competitors in recent years, as highlighted by Flight Global.

GE’s improved testing methodologies specifically target durability weaknesses observed in engines operating in arid environments, such as the Middle East.

Recently, the company introduced durability enhancement kits designed for the CFM Leap-1A turbofans, which are used in Airbus A320neo-family aircraft, featuring upgraded high-pressure turbine blades and nozzles.

Olivier Andries, the chief executive of Safran, noted in 2023 the challenges Leap engines face under severe conditions, particularly in regions such as the Gulf and India.

Design Modifications

GE has also rolled out similar enhancement kits for the Leap-1B engines that power Boeing’s 737 Max aircraft. Additionally, design alterations have been implemented to mitigate dust and sand-related durability issues affecting the GEnx and GE90 engines.

These improvements focus on components such as shrouds, nozzles, blades, and combustor linings.

Joe Vinciquerra, GE’s senior executive director of research, explained that the company previously lacked a comprehensive understanding of dust material constituents and their interactions with advanced material systems within engines.

Advanced Testing

GE is now capable of replicating dust environments to conduct experiments that mirror actual operating conditions, thereby enabling engineers to tackle durability challenges more effectively.

Throughout the development phase, the GE9X underwent 27,000 simulated flight cycles and 17,000 hours of operational testing.

The company began shipping production-ready GE9X engines to Boeing last year and plans to ramp up production in the latter half of this year.

Competitor Responses

Other companies competing in the aviation sector are also grappling with similar durability challenges, prompting them to allocate more resources toward finding solutions.

Pratt & Whitney is addressing widespread issues with its PW1000G geared turbofan family, while Rolls-Royce is focused on enhancing durability across various Trent engine models.

The durability package introduced by Rolls-Royce for the Trent 1000 engines is designed to prolong the life of high-pressure turbine blades and effectively double the service intervals between maintenance. Meanwhile, improvements for the Trent 7000 and Trent XWB-97 models encompass redesigned components and optimized combustors.

Stay informed with our latest updates by following us on social media.

Join our Telegram Group for the latest aviation news, and don’t forget to check us out on Google News.

Based on an article from aviationa2z.com: https://aviationa2z.com/index.php/2025/06/10/ge9x-to-power-777x-will-undergo-dust-ingestion-test/?utm_source=rss&utm_medium=rss&utm_campaign=ge9x-to-power-777x-will-undergo-dust-ingestion-test